|

|

What we are doing in the CMSE Lab.

Our general interest

Computational Materials and Process Design Technology on Hard Materials

(Metallic, Ionic, Semiconducting and Nano Device Materials),

through an Understanding of Fundamental Materials Properties

(Thermodynamic, Kinetic and Atomic/Nano Structural Evolution),

based on Atomistic Simulations, First-Principles Calculations and Computational Thermodynamics

What we have

What we are doing

|

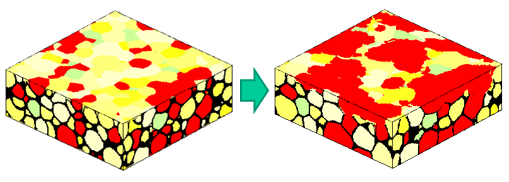

Prediction and Control of Microstructural Evolution in Polycrystalline Materials

- Multi-Scale simulations combining

- Phase Field Simulation (Microstructural Evolution)

- Computational Thermodynamics (Local Equilibrium)

- Atomistic Simulation (Interfacial Properties)

|

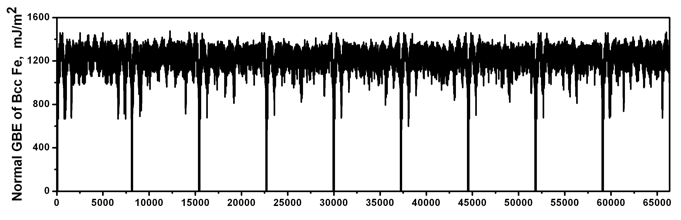

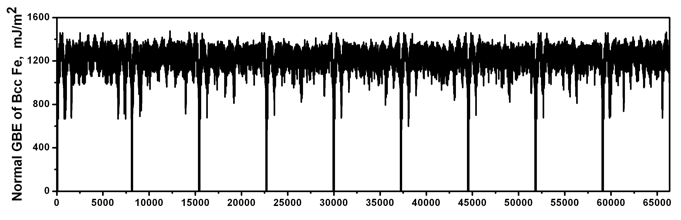

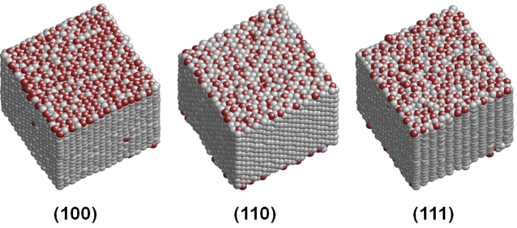

Grain boundary energy database |

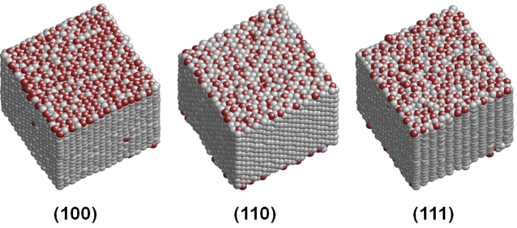

Anisotropic surface segregation of impurity atoms |

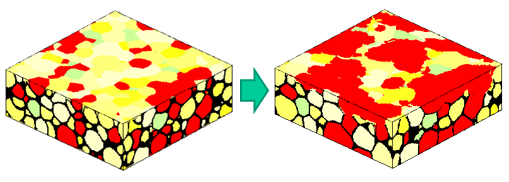

Phase Field Simulation

based on GB energy DB |

Phase Field Simulation of Surface Texture Formation |

|

|

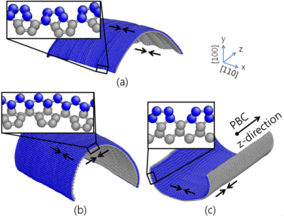

Atomic Scale Analysis of Nano-Structural Evolution

- Structural Evolution of Nano-structured Materials

- Effect of impurity atoms on Crack Propagation Behavior

- Effect of hydrogen and other impurity atoms

- Deformation Mechanism

- Design of Deformable Mg Alloys

- Process and Alloy Design of Low-Weight Steels

|

|

|

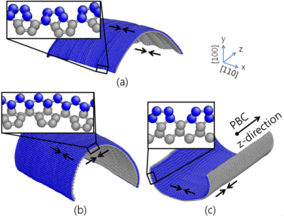

Spontaneous formation of

Si/Ge bilayer nanotubes |

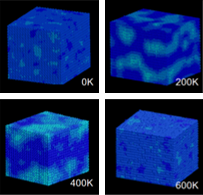

Phase Separation in GaInN thin films |

|

|

| Simulation of crack propagation |

Effect of impurity atoms on deformation behavior |

|

|

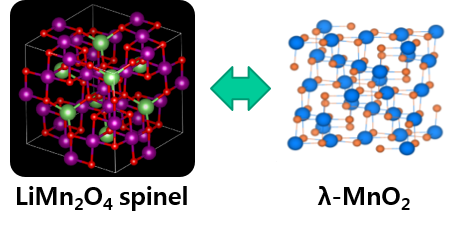

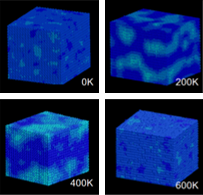

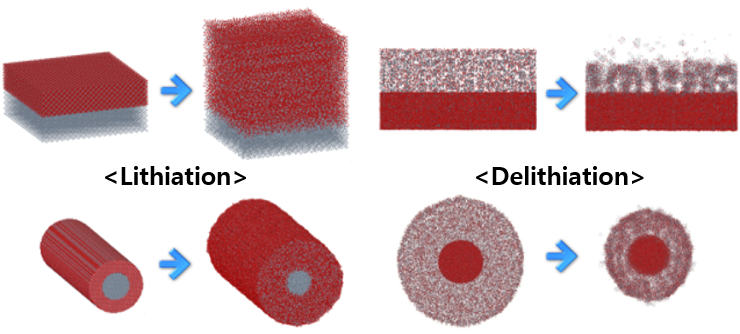

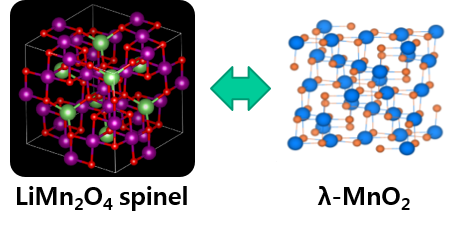

Computational Materials Design for LIB and post-LIB

- Structural Stability in Cathode and Anode Materials for Li-Battery and Post-LIB

|

|

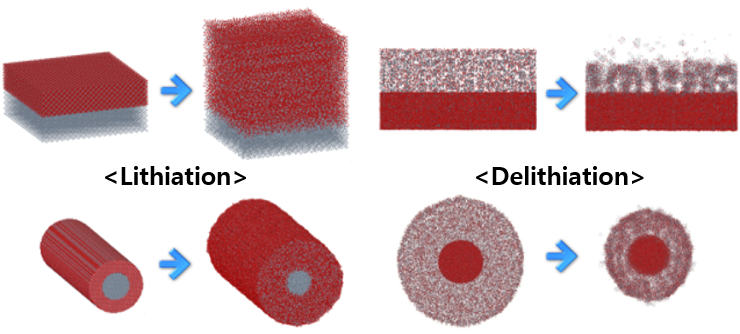

| Atomistic structural evolution during Lithiation and Delithiation of Si anode |

|

|

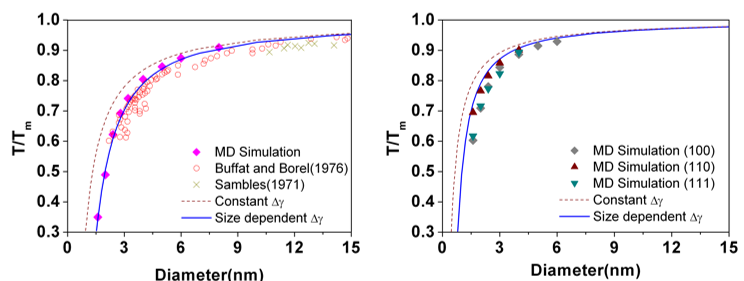

Infrastructure for Computational Approaches

- "Metallic + Covalent + Ionic" Interatomic Potential Database

- "Phase Field + Thermodynamics + Interface" Multi-scale Simulation Technique

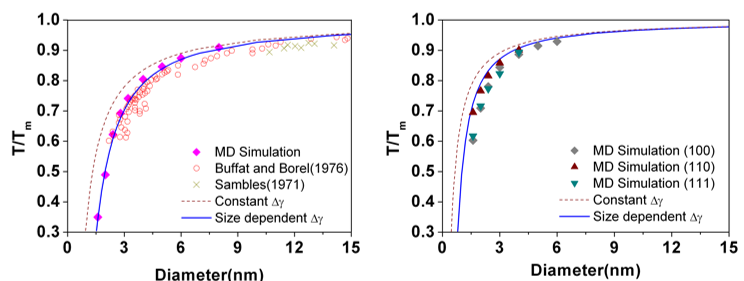

- Size Effect on Fundamental Physical Properties

|

|

|

Large-scale atomistic simulation

for oxide systems |

Melting point depression of nano particles & wires |

|

|

Sponsored researches

- Simulation tool for process and microstructure optimization in metal additive manufacturing (3D printing) (Mar. 2022 ~ Feb. 2026, from NRF)

- [ERC] Center for Heterogenic Metal Additive Manufacturing (Jun. 2022 ~ Feb. 2029, from NRF with Prof. HS Kim)

- Integrated Computer-Aided Process Engineering (ICAPE) for Aluminum Alloys (Apr. 2021 ~ Dec. 2026, from NRF with Kookmin Univ)

- Heat-resistant steel powder and feedstock for MIM (Apr. 2021 ~ Dec. 2025, from MOTIE with Prof. ES Lee)

- Process optimization of superconducting Nb3Sn growth (Oct. 2019 ~ Sep. 2022, from Kiswire Advanced Technology)

- Computational design and development of fcc high entropy alloys (May 2016 ~ Apr. 2022, from NRF with Prof. HS Kim)

- Machine-Learning based alloy powder design and manufacturing (Jul. 2018 ~ Dec. 2021, from MOTIE with Handong Univ)

- Low thermal expansion steels for application to hyperloop (Dec. 2020 ~ Sep. 2021, from POSCO)

- Process optimization of low-temperature packaging (Apr. 2021 ~ Mar. 2022, from Samsung Electronics)

- Atomistic modeling of nano catalysts (Jun. 2016 ~ May 2021, from NRF with KIST)

- Process optimization of advanced streel cord (Apr. 2017 ~ Sep. 2020, from Hyosung)

- Computational design and development of room-temperature deformable Mg alloys based on c+a slip-twining-texture correlations (Jun. 2016 ~ May 2019, from NRF)

- Atomistic modelling of Li-ion battery materials (from MKE with KIST)

- Computational design of new Ni-base superalloys (from MKE & ADD)

- Clarification of hydrogen effects in steels (from POSCO)

- Modeling and prediction of martensitic transformations during cooling and deformation (from POSCO)

- Capacity decay of Si anode for next-generation Li-ion battery (from NRF)

- Multicomponent Diffusion in Zn-coating layers of steels (from POSCO)

- Prediction of interfacial reaction between Al and Mg alloys (from POSCO)

- Effect of alloying elements on deformation behavior of Mg (from POSCO)

- Thermodynamic and Atomistic Modeling of Metal-Hydrogen Materials (from KIST)

- Computational Design of New Zr-alloys for Nuclear Power Plants (WCU-DANE, with Prof. M.H. Kim, ME-POSTECH)

- Atomistic Simulation of SiC Single Crystal Growth (from RIST)

- Atomistic Simulation for the mechanical properties of high phosphorus steels (from POSCO)

- Deformation mechanism of Bulk Metallic Glasses by Atomistic Approaches (from KIST)

- Thermodynamic and Atomistic Modeling of High Al Steels (from POSCO)

- Atomistic Modeling of MC, MN Carbonitrides (from KIST)

- Atomistic Simulation of Grain Boundary Mobility (from POSCO)

- Thermodynamic Modeling and Design of Fe-based Amorphous/Quasi-Crystalline Materials (from POSCO)

- Deformation mechanism and mechanical behavior of nano crystalline/amorphous matrix composite: molecular dynamics simulation study (from KIST)

- Development of Empirical Potential Database for MD/MC simulation on Nano Materials/Devices (from KRISS)

- Atomistic Simulation on Mechanical Property of Nano Architectures (from KOSEF, with Prof. J. Kim, ME-POSTECH)

- Development of Interatomic potentials of steel systems for simulation of irradiation damage (from KAERI)

- Characterization and Development of Alloy/Process Design Technology of High Nitrogen Corrosion-Resistant Steels using Atomistic Simulations (from KIMM)

- Calculation of Phase Equilibria and Fundamental Physical Properties of Steels using Thermodynamic Calculations and Atomistic Simulations (from POSCO)

- Development of an MEAM Interatomic Potential of the Fe-H system (from ExxonMobil Research & Engineering Company)

- Alloy Design of High Nitrogen Corrosion-Resistant Steels using Thermodynamic Calculations (from KIMM)

- Alloy/Process Design for Strengthening Automobile Steels using Thermodynamic Calculations (from POSCO)

- Thermodynamic Calculation of Hydride Reactions for Design of Hydrogen Storage Materials (from KIST)

- Alloy Design of Heat-Resistant Steels using Thermodynamic Calculations (from Doosan Heavy Industries & Construction Co., Ltd.)

- Atomistic Simulation Study on the Irradiation Damage of Nuclear Structural Steels (from MOST)

- Design of Metal/Carbon Nano Fiber Composite by Interfacial Reaction Control (from KIMM)

- Alloy Design and Property Evaluation of Amorphous/Nano composites using Computer Simulation (from KIST)

Last updated : 2023-01-03

|

|